No.4 - Lapis Co., Ltd.

What kind of company is Lapis?

Lapis is a company that manufactures oral care products and makes about 30,000 toothbrushes and tongue brushes a day. Other than products for which they receive orders from major manufacturers, they also carry many original products, and their signature product is the “one-tuft brush,” which is used at dental clinics and so on.The brush is cut into a distinctive cone shape and is useful for cleaning between teeth and so on.

What is so impressive about Daiichi Sogei?

①Constructs relationships with domestic and international manufacturers

While manufacturing major manufacturers’ products, Lapis also makes original products targeting dentists. It has partnerships with a wide range of manufacturers, including those that manufacture molds and brush fibers. It also has partnerships with foreign manufacturers and is prepared to be able to create products according to customers’ orders. In reality, it is frequently consulted by other manufacturers who have been rejected by other toothbrush manufacturers and are seeking a way around this, and it faces customers’ problems with the mettle of “not wanting to lose to major corporations despite its small scale.”

②Approaches other markets as well with converted ideas

Another trait of Lapis is its ability to plan. Other than oral care products for humans, it is also trying to manufacture toothbrushes, etc. for pets and have teamed up with trimmers that it encountered in Osaka to create products over three years. It also proposes plans for completely new products that are completely made from scratch, right from the materials of the hairs.

Techniques and Technology

① It has expertise in mold design and material selection

② It can print on acrylic

③ It also embeds toothbrushes by hand

Things Lapis is not equipped for

① It does not manufacture wooden brushes as it is worried about hangnails and mold due to humidity

② It is difficult to make the cross section of a brush three-dimensional

Main products we make

One-tuft brush

The phrase “preventive dentistry” has become commonly used, but in 2006, when the one-tuft brush started to be manufactured, the concept of effectively brushing teeth and reegularly going to the dentist to prevent cavities was still not widespread. Lapis saw that the concept of preventive dentistry had already taken root in Europe and started the manufacturing process in anticipation of it eventually becoming popular in Japan as well. It continues to focus on manufacturing in Japan so that customers can use them with peace of mind.

Inner workings of the factory

① One-tuft brushes are made by hand

For Lapis’ one-tuft brushes, hair transplantation is done by hand. The machines are customized into a form suitable for current manufacturing and used to carefully embed each strand into the brush. Brass parts are positioned in the middle of the brush fibers, hairs are transplanted as if embedding them, and after that, they are cut into a cone shape.

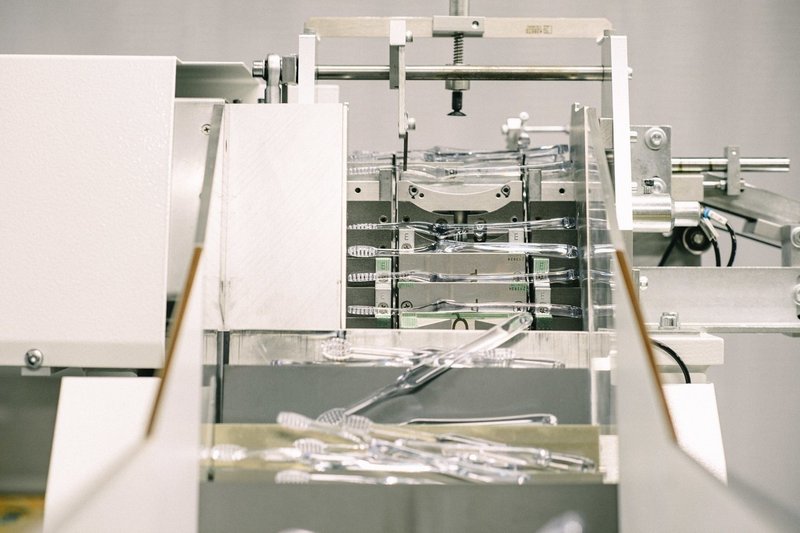

② Manufacturing, from hair transplantation and cutting to polishing, is carried out with integrated machines

The manufacturing or normal toothbrushes is carried out by controlling a machine. Controlled by a computer, all the steps, from hair transplantation and cutting to polishing the cut surfaces to become round, are carried out on a single manufacturing line. However, the process is not entirely left to the machines. If each section that does hair transplantation, cutting, and polshing does not send the products out at a specific speed, there might be congestion midway, leading to a decrease in efficiency. The speed must be adjsuted according to the holes in the brush in which hairs are transplanted so that it is not too fast nor too slow.

The love from the maker

LAs Lapis specializes in manufacturing toothbrushes, it does not have much freedom in manufacturing compared to other plants that participated in the YAOYA PROJECT this time. In particular, when it has to come up with a product in a short period of time, it also likely has to face the challenge of not being able to stray too far from the form of a toothbrush.

However, Lapis has the planning ability which was poured into the manufacturing of specialized products from the time that oral care literacy was still in development. We expect that it will be able to create products that will overthrow the impression that peole have of a conventional toothbrush while taking the time to conduct investigations and repeatedly carry out prototyping.

By the way, the diameter of a normal toothbrush is about 0.15mm-0.20mm. Toothbrushes for pets are as thin as 0.127mm. They are made of materiasl that only experts have the opportunity to touch and have a unique feel. Other than toothbrushes, it might also be able to discover new possibilities. We also warmly welcome proposals for products not related to oral care! We hope to receive many new ideas that would not occur to us.

Official HP:http://www.lapis21.com/

View other entries

No.1 - Fujita Metal Manufacturing Co., Inc.

No.2 - Hototogisu Co., Inc.

No.3 - Daiichi Sogei Co., Inc.

No.4 - Lapis Co., Inc.

No.5 - Kinjo Rubber Co., Inc.

No.6 - Akasaka Engraving Lab

No.7 - O-TWO Co., Inc.

No.i8 - Runeseikou Co., Inc.

About the YAOYA PROJECT

この記事が気に入ったらサポートをしてみませんか?