No.6 - Akasaka Engraving Lab

What kind of company is Akasaka Engraving Lab?

The "Akasaka Half Moon Engraving Method" was established by first generation engraver Hyounosuke Akasaka. Akasaka Engraving Lab is a metal processing and mold manufacturing company that combines the latest processing machines with highly developed carving techniques that have been passed down for generations. The products are of such a high quality that they can stand up to even the strictest scrutiny. The spirit of honest craftsmanship is alive even today, preserved through the use of state-of-the-art computer technology. The work is characterized by clearly defined edges in even the most intricate engravings, and is suitable for customizing small metallic items such as home appliance parts, logo plates, stamps and frying pans. The technology has become even more advanced in recent years, and it is now possible to transfer photographs to metal plates.

What is so impressive about Daiichi Sogei?

① Fusion of manual techniques and machine technology developed over three generations

Akasaka Engraving Lab was founded in 1940. The “Akasaka Half Moon Engraving Method” came about as a result of the first generation engraver losing his left hand in a workplace accident, and needing to figure out how to counteract the force of the chisel. The second generation engraver introduced a computer-controlled processing machine to the method, combining traditional and innovative technologies to continue the development of the craft. There are other companies that use computers in their process, but there are few places where they can make their own blades. The knowledge of how to make a blade with a tip that is thinner than human hair has been passed down through the generations, making it possible to create incredibly fine engravings.

② Absorbing of external knowledge and using it in manufacturing

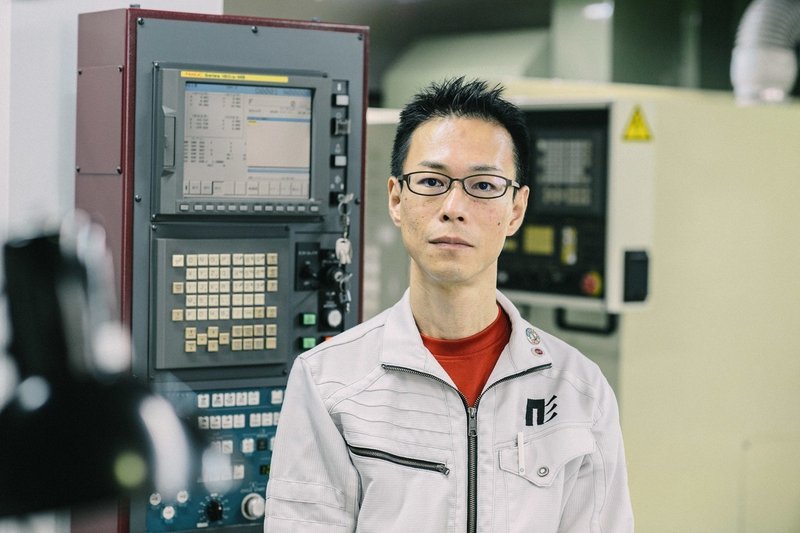

Mr. Takehiro is the third generation engraver who is brimming with curiosity and actively communicates with other craftsmen. As a part-time instructor at Osaka Institute of Technology and with a deep knowledge of handmade mail order sites, he goes against the typical image of a craftsman. He is currently exploring the processing and utilization of biodegradable plastics in order to research and build prototypes that will meet the needs of the next generation whilst also respecting traditions.

Techniques and Technology

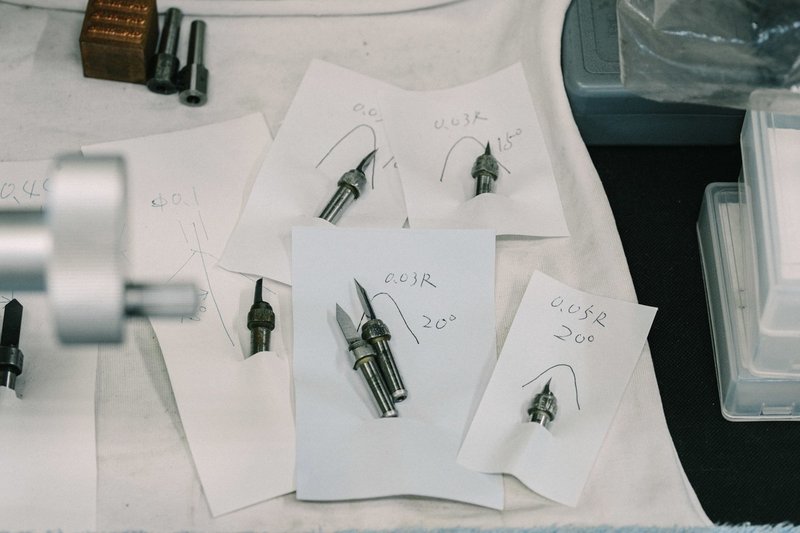

① Fine blades with a tip of about 0.05mm which can be manufactured in-house

② Engraving blades can be manufactured to match the content and materials of each job

③ Simple injection molding for hobbies and teaching materials etc. can also be manufactured

Things Akasaka Engraving Lab is not equipped for

① Machining of metal pieces larger than A4 size

② Metal processing such as folding and bending

③ Rough machining with a thick blade

Main products we make

Molds

Molds are indispensable for plastic and resin molding. Mr. Akasaka's molds include clearly defined raised and recessed parts, and even small details stand out. Using a blade so fine that the tip cannot be seen without a microscope, a reversed image is engraved onto a metal surface to create a mold. For example, Akasaka makes molds for the resin caps used in Asahi Shuzo Co., Ltd.'s signature product, “Dassai Sparkling”. The fine details of the kanji are carved beautifully, and the engraving has defined edges on the curved surface, making its precision stand out even when compared to work by other companies.

*Front: Cap made with Akasaka's mold / Back: Cap from another company's mold

Inner workings of the factory

① Beginning by making an engraving blade

In order to engrave fine details, it is necessary to first make a fine engraving blade. Although the main focus has shifted from hand-engraving to computer processing, the quality of a piece of work can vary greatly depending on the quality of the blade. In addition to making metal sculptures themselves by carving metal rods, we have highly refined adjustment skills to ensure that even an extremely thin blade will not lose to the engraving surface.

② Performing processing at a level that can only be seen with a magnifying glass

We face the question of how to use the technology we have to answer the customer's question, “Can you do this?” Sometimes there are requests for fine engraving that can only be seen with a magnifying glass. Although we don’t make large products, our skills at manufacturing finely detailed objects are in the top class in the industry.

The love from the maker

My grandfather, the first generation engraver Hyounosuke Akasaka, was a genuine craftsman. Immediately after losing his left hand in an accident involving the press machine, he went back to work engraving by creating a prosthetic hand with a mechanism that fixed his chisel (engraving blade) in place. The “Akasaka Half Moon Engraving Method”, which is the base of our current technology, was developed by my grandfather after he lost his hand so that he could engrave metal effectively despite his lack of strength.

There are many other skilled craftsmen besides me. However, I don’t think that there are many other people who have the curiosity to explore the knowledge of other industries and use it in their own work, while also mastering the engraving techniques that have been handed down to them. I’m trying to make myself sound cool, but actually I just like to look into things that interest me… (laughs)

I’ve always been making things ever since I was little. I want to express that sense of enjoyment to the next generation. That’s why I teach at universities and orphanages. I want to help raise the next generation of craftsmen.

In a way, metal is a substance that can be made into any shape. I would be happy if that same sense of “unlimited possibility” could be applied to other things that would make people happy, like food for example. I mean, people are happy when they eat food, right?

Official HP:https://www.cho-cocu.com/

View other entries

No.1 - Fujita Metal Manufacturing Co., Inc.

No.2 - Hototogisu Co., Inc.

No.3 - Daiichi Sogei Co., Inc.

No.4 - Lapis Co., Inc.

No.5 - Kinjo Rubber Co., Inc.

No.6 - Akasaka Engraving Lab

No.7 - O-TWO Co., Inc.

No.8 - Runeseikou Co., Inc.

About the YAOYA PROJECT

この記事が気に入ったらサポートをしてみませんか?